Over the past few decades, 3D printing technology has made remarkable advancements, revolutionizing industries across the globe. Malaysia, too, has witnessed the transformative power of 3D printing, as it disrupts traditional manufacturing processes. This article delves into the evolution and impact of R3Dprints in Malaysia, shedding light on its concept, industries it influences, and the reasons behind its widespread adoption.

Understanding the Concept of 3D Printing

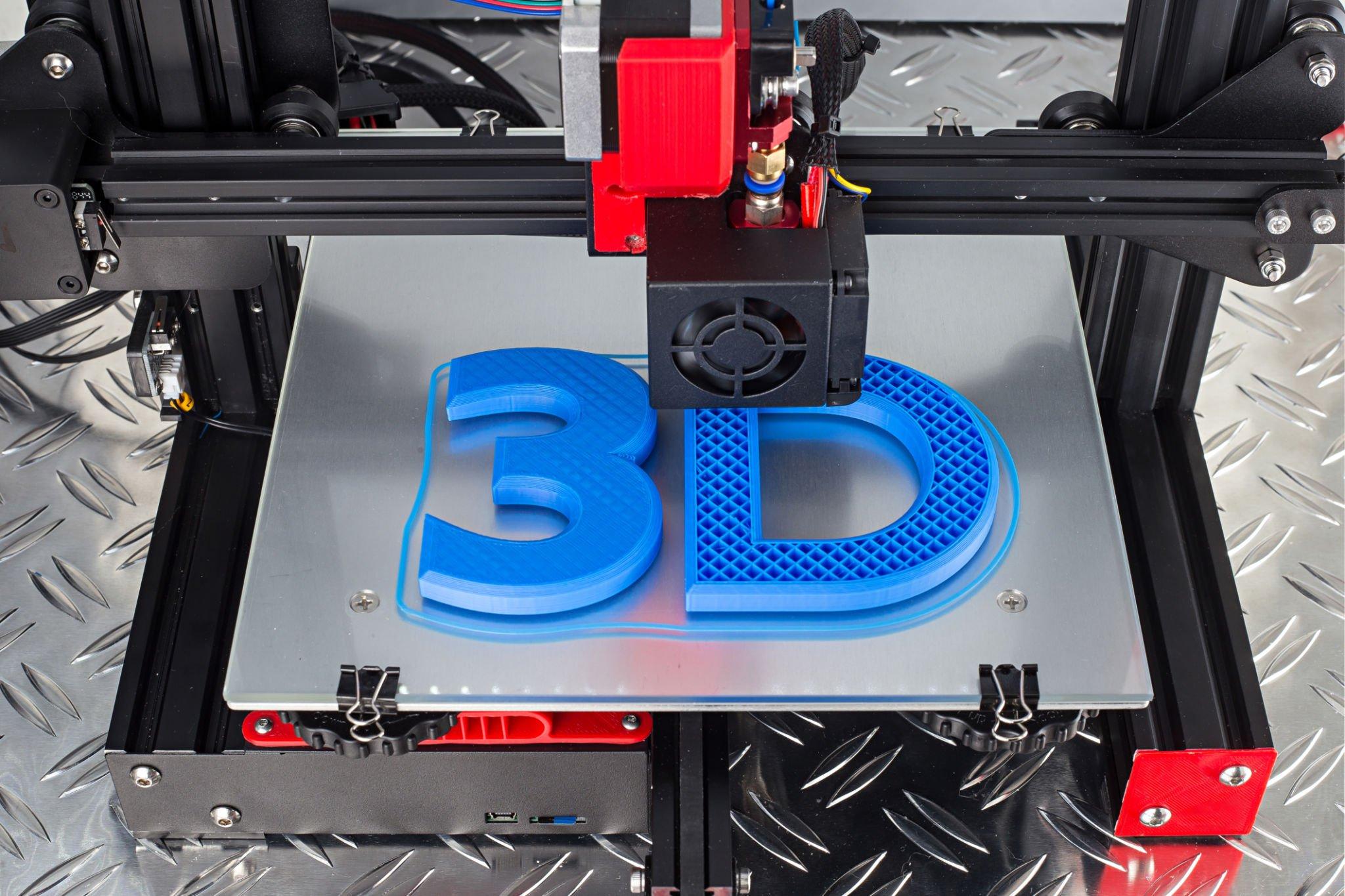

3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects by layering materials based on a digital design. Unlike traditional subtractive manufacturing methods, where materials are carved or molded, 3D printing builds objects layer by layer, offering greater design flexibility and complexity.

Advancements in Industries:

Manufacturing: 3D printing has transformed the manufacturing landscape in Malaysia. The automotive industry utilizes 3D printing for prototyping, customized spare parts, and tooling. It accelerates production, reduces costs, and enables on-demand manufacturing.

Healthcare: 3D printing plays a vital role in the medical field, facilitating the production of patient-specific implants, prosthetics, and surgical guides. It enhances treatment outcomes, reduces surgical risks, and enables faster recovery.

Architecture and Construction: The construction industry is exploring 3D printing for building components and even entire structures. This technology offers efficient and cost-effective construction methods, reduces material waste, and enables architectural innovation.

Aerospace: 3D printing enables lightweight and complex aerospace components, enhancing fuel efficiency and reducing aircraft weight. It speeds up the prototyping process and enables rapid iteration of designs.

Reasons for Widespread Adoption:

Design Freedom: 3D printing enables the creation of intricate designs and complex geometries that were previously challenging or impossible to produce. This freedom allows for customized and optimized products.

Cost and Time Efficiency: The ability to produce objects on-demand and eliminate traditional manufacturing constraints significantly reduces production time and cost. This benefit appeals to businesses seeking streamlined operations.

Sustainable Manufacturing: 3D printing minimizes material waste as it only uses the required amount of materials for each object. This environmentally friendly approach aligns with Malaysia’s commitment to sustainability.

Accessibility: The increasing availability of affordable 3D printers and user-friendly software has made this technology more accessible to individuals, hobbyists, and small businesses, fostering creativity and innovation.

Conclusion

The evolution of 3D printing technology has brought about transformative changes across various industries in Malaysia. From automotive and healthcare to architecture and aerospace, 3D printing offers unparalleled design freedom, cost efficiency, and sustainability. As Malaysia embraces this technology, businesses can unlock new possibilities for innovation, productivity, and competitiveness. The future holds even greater potential for 3D printing advancements, shaping a world where customized, complex, and sustainable manufacturing becomes the norm. By staying at the forefront of this technology, Malaysia can continue to reap the benefits of 3D printing’s evolution and impact for years to come.